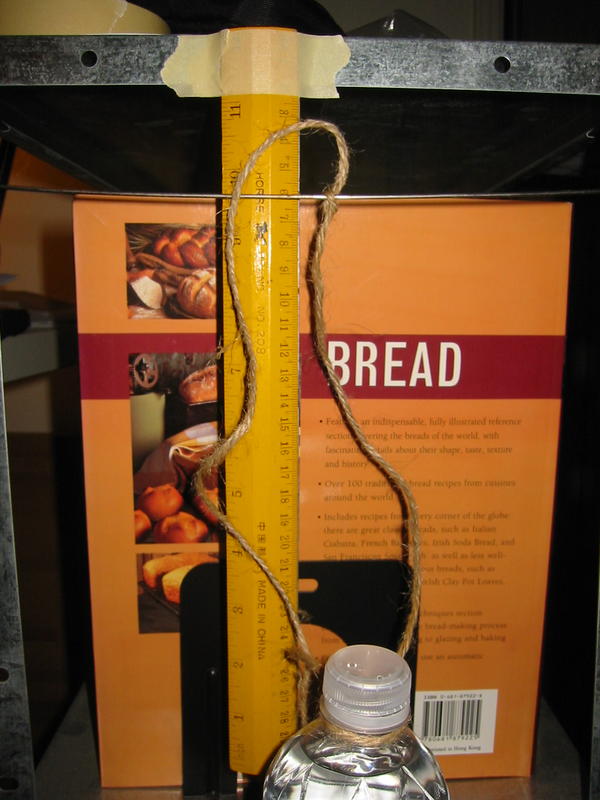

The precision testing jig. The spoke is a 15ga, 1.8mm diameter spoke. It is loaded with a precision weight of approximately 500g of water (plus 20-30g of bottle and string). The span between the spoke supports is 270mm. The spoke is resting loosely on two bolts, that is, the bolts aren't clamped down and the spoke can move freely. When loaded the spoke is at about 82mm on the ruler.

When unloaded (by lifting the water bottle) the spoke relaxes to about 60mm on the ruler. The spoke isn't quite straight so it's necessary to measure the relative displacement between loaded and unloaded, 82-60=22mm. This is repeatable to about 1mm.

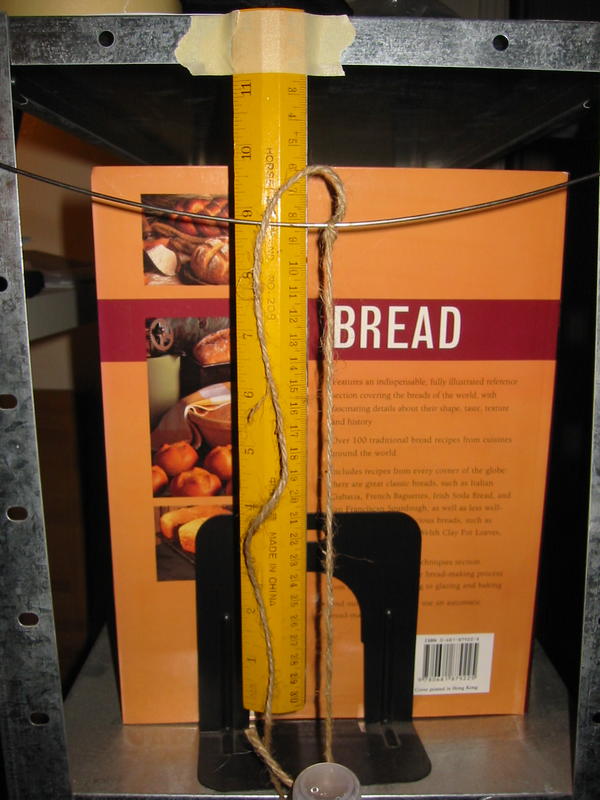

A closer picture to show the ruler scale when loaded, with the spoke at about 82mm. When cycled, the spoke comes back to the same places, showing that its bending is elastic (reversible).

How much should the spoke deflect? The standard formula for bending of a beam loaded at the center is

w = FL^3 / 48EIwhere w = displacement, F = load force, L = length between supports, E = modulus of elasticity, and I = cross-sectional moment of inertia of the beam. For a round beam, I = pi r^4/4, so for a 1.8mm diameter spoke, I = 0.52 mm^4. For typical stainless steel, E is about 29,000 ksi (kilo-lbf/in^2) = 200 GPa = 200 kN/mm^2. The load force is F = 0.52 kg * 9.8 m/s^2 = 5.1 N. L is 270 mm.

This yields an estimate of w = 20.1 mm predicted, and 22 mm measured, so the theory and practice agree to about 10%.

If we (erroneously) interpreted the displacement as limited by tension in the spoke, we would calculate the displacement as

w = FL / 4T , thus T = FL / 4w.This would give us T = 15 N (for the measured w = 22 mm), or tension T = 1.5 kgf. This is not zero, but it is small compared to spoke tensions in actual wheels, which are around 60-100 kgf. What this tells us is that for purposes of resisting displacement over the entire length of the spoke, spoke bending stiffness is essentially negligible compared to typical spoke tensions.

Note the disclaimer about the entire length of the spoke. If you measure over a very short length, bending stiffness becomes more important due to the L^3 dependence of the displacement. This is presumably one reason that spoke tensiometers usually have the posts several inches apart, to keep L relatively large.