DEIMOS Has First Light June 3

First light went almost flawlessly. The weather was beautiful, we were integrated with the telescope and guider within about 2 hours after opening up. When we pointed to the first star (in twilight), it fell near the center of the guider! By the end of the night we had aligned with a slitmask to check the astrometry and had acquired all the basic photometric and spectrophotometric calibration data. Pictures soon! 11 May: Drew has been in Hawaii for the past week. We are

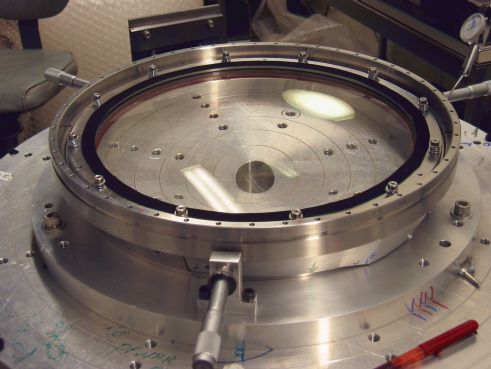

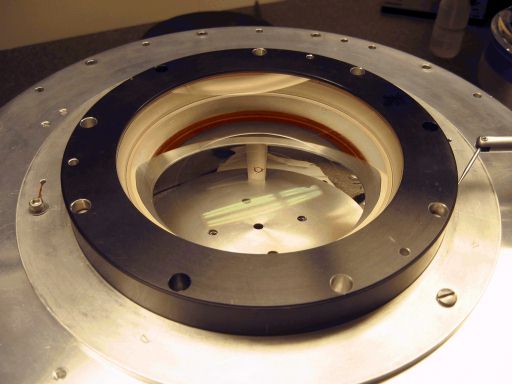

currently in the process of adjusting the kinematic mounts to place DEIMOS's

rotation axis on the elevation axis (ie optical axis) of the telescope.

This has proceeded in 3 stages: (a) CARA put in a cross-hair on one elevation

axis, and a "target" on the AO optical rotator, which is believed to be

precisely on axis; (b) DEIMOS moved into observing position, and

autocollimator aligned on the two points above defining the elevation axis; and

(c) DEIMOS aligned to the autocollimator. Due to the small sight angle through

DEIMOS, we have had to perform (b) and (c) twice, first to place DEIMOS

approximately on-axis so that we had a clear sight of the cross-hair/target

defining points, and then for the final alignment of autocollimator and

instrument.

We are in the process of finishing with (c) for the final pass.

30 May: Drew is back in Hawaii. This page needs a lot of work,

but for now here are some pictures of current problems:

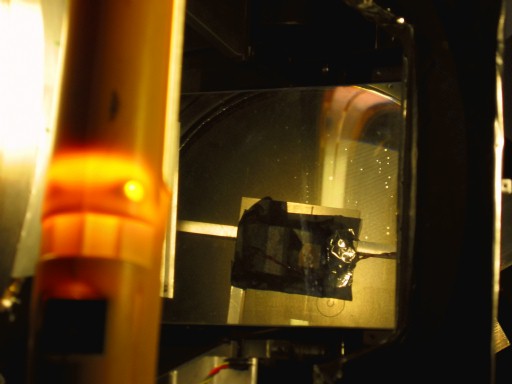

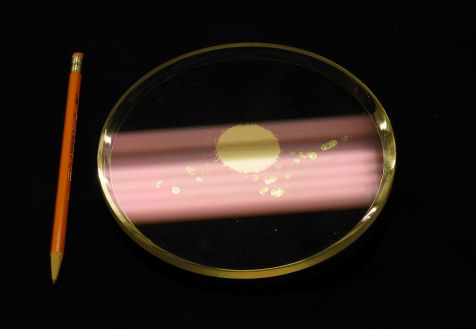

Bubbles in Optical Couplant fluid between Elem 5 and 6:

Another photo with Flash lighting

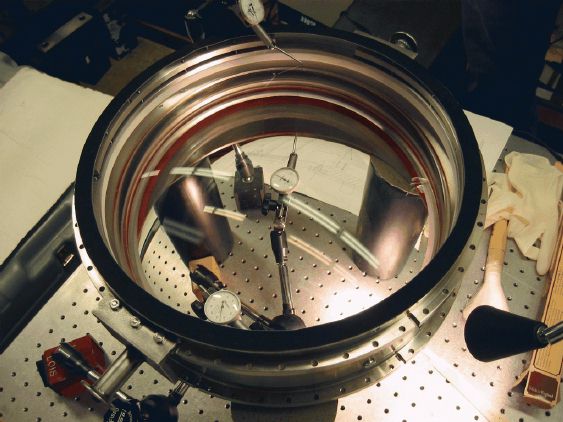

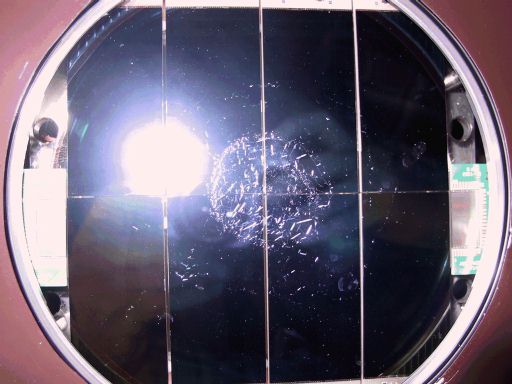

Degradation of Collimator and Tent mirror Coatings:

Collimator coating detail 2

The largest spot is several mm across including outer halo.

31 May: PRM light leak appears to be fixed. This was a problem

where the PRM sensor, located on the grating box, seemed not to turn its

LED completely off, leading to a high background light level in long

exposures. After we identified the PRM sensor LED as the culprit,

Bob Kibrick found in Santa Cruz that very low current levels could

indeed cause these LEDs to glow faintly. A fix was derived; the

requested resistor installed in the interconnect box, and the latest

"dark" exposures show no trace of the characteristic shadows cast

by the PRM sensor LED.

The PXL guide camera has been restored to health, images obtained

and analyzed in preparation for first light on June 3.

Other news:

(To be added)

News from Hawaii