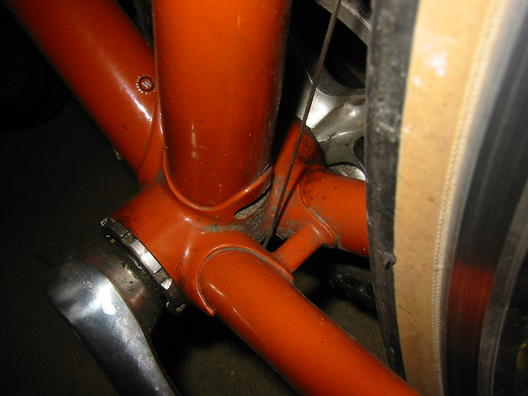

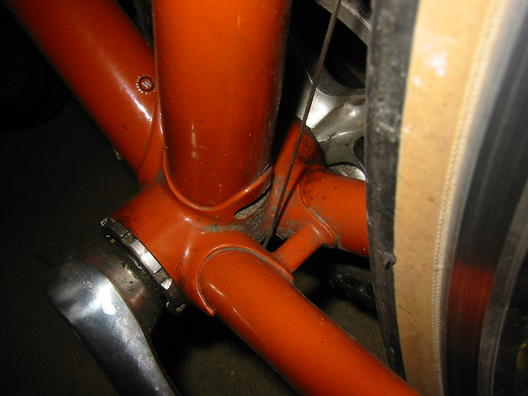

Classic steel frame construction. Chainstays are probably Columbus SP, round chainstays, 22mm diameter, chainstay bridge 10mm diameter. Stiffness in bending goes as about 3rd-4th power of diameter (depending on wall thickness) and first power of wall thickness. How much stiffer is a 22mm tube than a 10mm tube? A lot. Note adding the bridge keeps the tire from getting stuck (this frame does have horizontal dropouts) but puts a fillet braze right at a high stress location. Nevertheless about a zillion frames are successfully built this way.

Steel frame construction. Chainstays might be 531, oval chainstays, 21x27mm diameter (long ways vertical). Chainstay bridge 9mm diameter, and actually part of the BB shell lugs. Avoids an extra braze to the stay at the location of the bridge (and an extra step in fabrication). Small size of the bridge and its closeness to the BB shell emphasize its vestigiality, in terms of contributing to stiffness or redistributing stress.

Aluminum frame construction, welded. Oval chainstays, 19x31mm diameter (long ways vertical), no chainstay bridge. Chainstays are gusseted on the inner surface. This is a cross bike, and aluminum, so the designers may have felt it needed reinforcement. Note that the gussets are welded at top and bottom edges but not all the way around. This might be to avoid putting a weld right in the middle of the stay, where much of the stress is, and/or to avoid building in stress due to distortion of the stay and gusset during welding. Or maybe it's to provide a convenient pocket for storing dirt.